Aspect Ratio

What is Aspect Ratio? Aspect Ratio (AR) is a number that represents the relationship between the thickness of the wire (wire diameter) used to make a jump ring and the inner diameter of that jump ring. Each chain maille weave has an ideal AR, or an ideal AR range, that ensures jump rings of that AR can be used to make the weave and produce the desired look and degree of flexibility.

When you buy jump rings, the inner diameter sizes listed usually represent the mandrel size used to make the jump ring and not the actual inner diameter of the jump ring. The actual inner diameter will be slightly different from the mandrel size due to spring back*.

There can be variations in stated jump ring sizes from different jump ring suppliers and even in different batches and colors from the same supplier. In addition, different metals have different working properties. Therefore, the degree of spring back* varies from metal to metal and can affect the finished size of jump rings made from different metals but coiled on the same mandrel. This is why AR is a more accurate way to choose appropriate jump rings for your project.

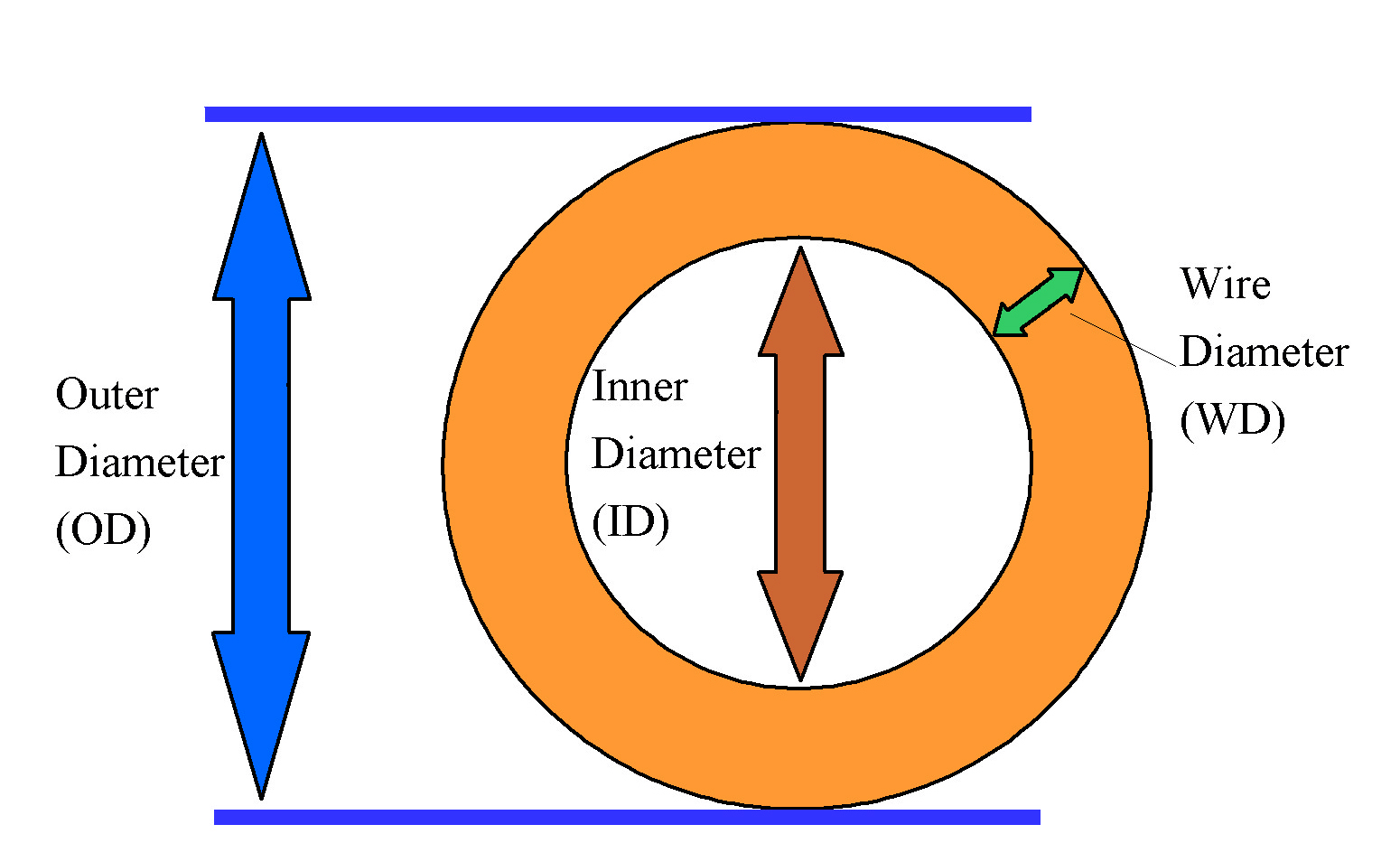

How Do You Determine Aspect Ratio? To determine Aspect Ratio, divide the inner diameter (ID) of the jump ring by the wire diameter (WD) of the jump ring (see formula 1 below). Make sure that both your WD and ID measurements are in the same measuring system (imperial or metric). Note that the gauge of the wire is not the WD measurement. Also, be aware that there are 2 commonly used wire gauge systems AWG and SWG. You can easily find wire gauge charts and imperial to metric (and vice versa) converters on the internet to help you get your numbers right. Here are a few links that I’ve found useful.

Once you determine the AR of the jump rings you are using for a particular weave, you can use that AR number to help you determine what size jump rings in other wire gauges will also work with that weave (see formula 2 below).

To do AR math, you’ll need to know these 3 measurements – ID (inner diameter), WD (wire diameter), and OD (outer diameter). ID and WD are the most important measurements for chain maille. Here are the formulas you will need to do AR math:

- To Determine Aspect Ratio: ID ÷ WD = AR

- To Determine Jump Ring Size: WD x AR = ID

- To Determine ID: OD – (2 x WD)

- To Determine OD: ID + (2 x WD)

- To Determine WD: ID ÷ AR = WD

Examples:

You made a Byzantine chain using 18g AWG, 3.5mm ID jump rings and now you want to make the same weave using 16g AWG jump rings. How do you figure out the appropriate ID for the 16g AWG jump rings?

First, determine the AR of the jump rings you used to make your 18g AWG Byzantine chain.

3.5mm ID ÷ 1.024mm WD = 3.417 AR (round to 3.4)

Now multiply that AR by the 16g AWG wire diameter to determine the correct ID.

3.4 AR x 1.290mm WD = 4.386mm ID (round to 4.4mm)

The closest commercially available ID size is 4.5mm. Therefore, you would buy 16g AWG, 4.5mm ID jump rings to make your 16g AWG Byzantine chain.

What if you want to make that Byzantine chain using 16g SWG jump rings instead? You can use the same formula. Just plug in the 16g SWG wire diameter measurement instead.

3.4 AR x 1.626mm WD = 5.5284mm ID (round to 5.5mm)

In this case, you’ll need 16g SWG, 5.5mm ID jump rings to make your Byzantine chain. I wanted to get an imperial ID measurement instead, so I used the link above to determine that 5.5mm = 7/32”.

All you need to know is the AR of any weave you want to make (you can find recommended ARs for weaves on the M.A.I.L. website). Then, you can use this same formula to determine the size jump rings you’ll need. Just multiply the AR by the wire diameter you want to use. **

In the examples presented, the wire diameter measurements were taken from wire gauge charts and the ID measurements used reflect mandrel size. For many of your basic weaves, those numbers are good enough. However, some weaves are much more sensitive. When a more accurate result is required, use calipers to measure the actual WD and ID of your jump rings and use those measurements in your calculations.

NOTE: The above applies to weaves that are made using 1 jump ring size and round wire only. Using multiple sizes in a weave, or using fancy wire shapes, will necessitate some experimentation.

*Spring back – When you release wire after coiling it around a mandrel to make jump rings, the wire attempts to return to its original shape and unwinds a bit. This results in jump rings with an inner diameter that is slightly larger than the size of the mandrel. I made a short video to demonstrate this. Click here to see it.

**Keep in mind, this is not a perfect world. There are real-world variables that the math does not account for, such as differences in jump rings based on supplier, batch, color, metal, etc. Therefore, you still might have to experiment a little with sizes to find the perfect jump rings for your project. When purchasing jump rings, always reference not only the stated size of the jump rings, but also the supplier’s stated AR of the jump rings.