What to Consider When Choosing Pliers (Part 2 of 4)

In the previous installment of this blog, I discussed the personal factors you should consider when trying to decide on an appropriate pair of pliers. Now I’ll present the first of three attributes to examine when trying to choose which pliers to use – the jaws of the pliers.

JAWS:

I make chain maille jewelry. Most of my work is made with smaller sized jump rings in precious metals or aluminum. I always choose smooth jawed pliers, as pliers with serrated jaws will leave marks and scratches on the metals I work with (more on marring jump rings in a future blog post).

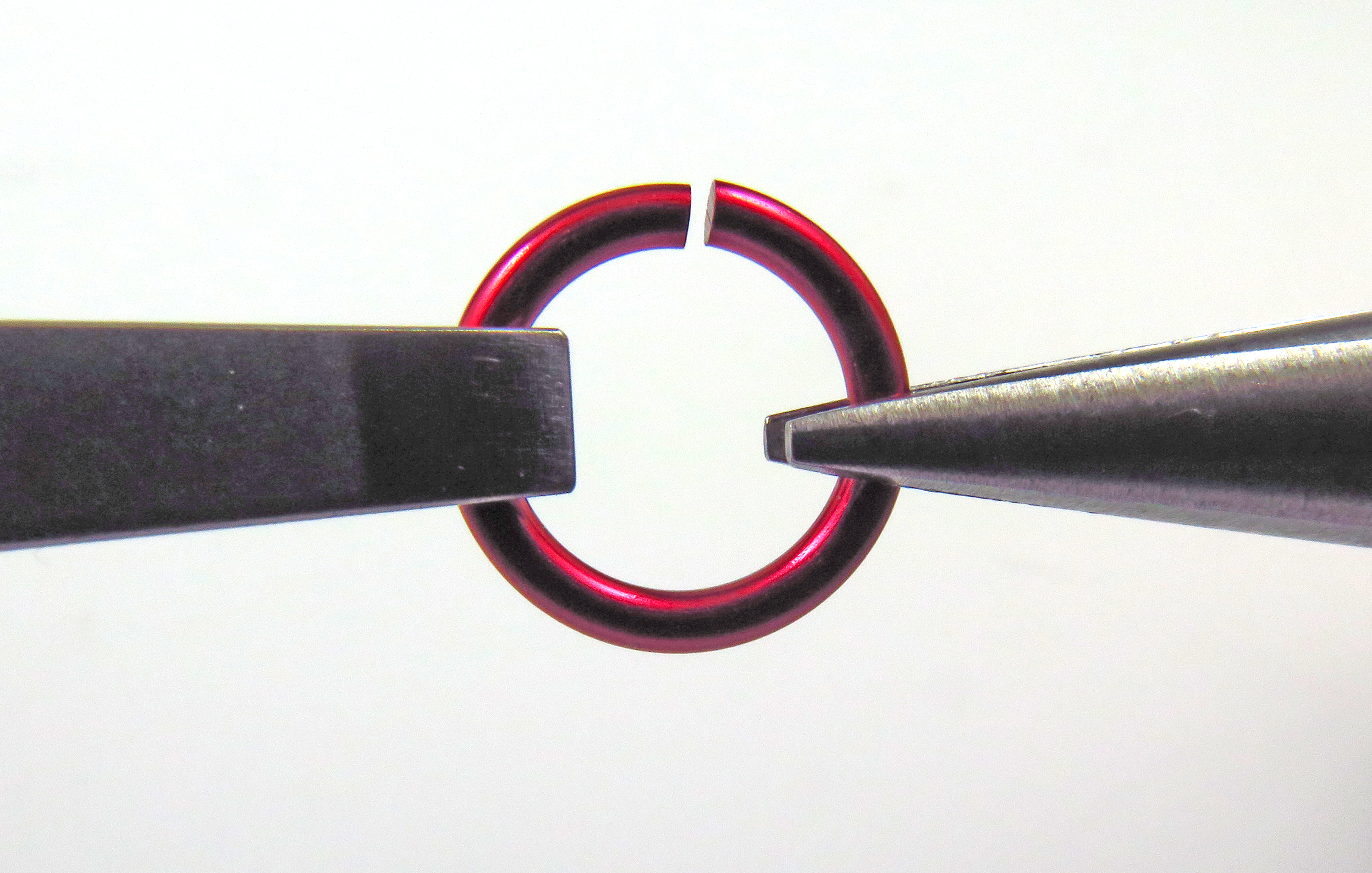

Generally, I prefer flat nose pliers over chain nose pliers for chain maille. As you can see in the photo above, flat nose pliers (left), cover more surface area on the jump ring than chain nose pliers (right). This gives you more control and more leverage. In addition, you are more likely to mar the surface of your jump ring with chain nose pliers. The force applied to the pliers gets concentrated at the tip of chain nose pliers, as opposed to being distributed across the width of flat nose pliers, causing it to dig deeper into the metal.

I choose different size flat nose pliers based on the size of the jump rings I’m working with, the metal I’m using and the weave I’m constructing. When weaving using medium sized jump rings (16g-18g), I use medium size flat nose pliers. I have a pair of ergonomic Lindstrom flat nose pliers, a pair of Swanstrom flat nose pliers, and a pair of Tronex flat nose pliers (above). The width of the plier jaws on these models is about 4mm. These are all quality pliers and all are well suited for the task. These are my 3 most expensive pairs.

I choose different size flat nose pliers based on the size of the jump rings I’m working with, the metal I’m using and the weave I’m constructing. When weaving using medium sized jump rings (16g-18g), I use medium size flat nose pliers. I have a pair of ergonomic Lindstrom flat nose pliers, a pair of Swanstrom flat nose pliers, and a pair of Tronex flat nose pliers (above). The width of the plier jaws on these models is about 4mm. These are all quality pliers and all are well suited for the task. These are my 3 most expensive pairs.

I really enjoy working with smaller jump rings (18g and higher). When I work small, I reach for one of my Xuron pliers (flat nose, short flat nose or chisel nose). These pliers are less expensive than those mentioned above, but are very well made. The Xuron company also provides excellent customer service if an issue should arise. The width of the jaws of these pliers ranges from 2mm to 3mm. The shorter flat nose provides more leverage when needed. The angle of the chisel nose increases surface contact and can be helpful for getting into tight spots. Because the Xuron pliers weren’t as costly as those mentioned above, I felt free to modify the jaws on both flat nose pairs. I thinned the jaws to help them fit into tight spaces (details will be covered in a future blog post).

I really enjoy working with smaller jump rings (18g and higher). When I work small, I reach for one of my Xuron pliers (flat nose, short flat nose or chisel nose). These pliers are less expensive than those mentioned above, but are very well made. The Xuron company also provides excellent customer service if an issue should arise. The width of the jaws of these pliers ranges from 2mm to 3mm. The shorter flat nose provides more leverage when needed. The angle of the chisel nose increases surface contact and can be helpful for getting into tight spots. Because the Xuron pliers weren’t as costly as those mentioned above, I felt free to modify the jaws on both flat nose pairs. I thinned the jaws to help them fit into tight spaces (details will be covered in a future blog post).

I also have a few “specialty” pliers that I use from time to time:

• Bent nose pliers: can be used like a flat nose or chain nose plier

• Stepped flat nose pliers (with narrow flat tips): for small jump rings in tight spots (photo above shows pliers before modifications – shown with modifications in a future blog post)

• Snub nose pliers: for medium sized jump rings in tight spots

• Duck bill pliers: for jump rings that have a large inner diameter

People who choose to work with low wire gauges and harder metals, such as stainless steel and titanium, will need a set of heavy-duty pliers such as linesman’s pliers or armorer’s style pliers. These are pliers of sturdy construction, typically with shorter jaws to provide more leverage; some may have teeth.

Previous Installment: Part 1 – Personal Considerations

Next Installments: Part 3 – Springs, Part 4 – Handles